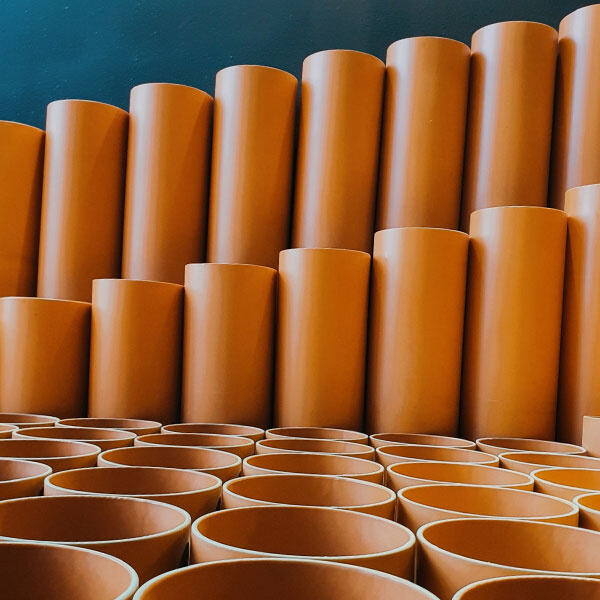

K-resin என்பது பல விஷயங்களுக்கு பயன்படுத்தக்கூடிய ஒரு பிளாஸ்டிக் வகையாகும். இது இரு முக்கிய வேதியியல் பொருட்களை மூலம் உருவாக்கப்படும்; ஸ்டைரீன் மற்றும் புட்டாடியீன். இந்த இரண்டு வேதியியல் பொருட்கள் ஒன்றுடன் ஒன்று இணைந்தால், அது சுத்தமான கடுமையான பிளாஸ்டிக்கை உருவாக்கும், அது சாதாரண பிளாஸ்டிக்குகளை விட மிகவும் தாக்குதலாகவும் நீண்டவுடனும் உள்ளது.

K-resin பற்றியும் மாறுபட்டது, அது உங்களுக்கு தேவையான எந்த வடிவத்தினாலும் செயல்படுத்தப்படலாம். k-resin தயாரிப்பு அலுவாக்கள் மற்றும் விளையாட்டுகளால் பல பொருட்களை உருவாக்க வழியாகி வருகிறது; அவற்றில் பொட்டிகள், கொள்கலன்கள், சிறுசிறு ஆட்டக்குறிகள் மற்றும் மருத்துவர்கள்/பருவாளர்கள் பயன்படுத்தும் மருத்துவ உபகரணங்களும் உள்ளன. இதனால் k-resin மிகவும் ஏற்றுமையாகவும் பல வழிகளில் பயன்படும் தன்மையும் கொண்டது.

பெருமை ஒரு தொழில்நுட்ப க்குறிப்புக்கு மற்றும் k-resin ஐ பயன்படுத்துவதற்கான ஒரு தேர்வு. இந்த பொருள் நிறுவனங்களால் மற்றும் வியாபார நிறுவனங்களால் தங்கள் உற்பத்திகளுக்கான மிகவும் தாக்கத்தக்க மற்றும் மிகவும் எளிதாக மேற்கொள்ள முடியும் தொடர்புகளை உருவாக்க பயன்படுத்தப்படுகிறது. K-resin பெருமை பெரும்பாலும் பயன்படுத்தப்படும் ஒரு காரணம்... இது பொருட்களை பாதுகாத்துவதில் மிகவும் நல்ல பணி செய்கிறது. இது ஒலிப்பு தாக்கத்திற்கு மற்றும் கீமிய தாக்கத்திற்கு எதிராக தங்கியிருக்கும், அதனால் உற்பத்தியை ஒரு இடத்தில் தங்கியிருக்க வேண்டும் என்றாலும் அது பெருமை தாக்கத்திற்கு முன்னோடி பாதுகாப்பு செய்யும்.

K-resin அதிர்ச்சி தெளிவுடன் இருக்கிறது, இது பல நிறுவனங்கள் அதனை தரப்பு பயன்பாடுகளுக்கு மையமாக அணிந்து கொள்ளும் என்பதை விளக்குகிறது. ஆக, வாங்கும் முன்னரே வாங்குவார்கள் பெட்டியில் உள்ளது என்ன எளிதாகக் காணலாம். K-resin பெட்டிகள் அதிர்ச்சியாக அழைக்கும் வண்ணங்களில் தயாரிக்கப்படுகின்றன, இதனால் கடைகளின் அறைகளில் குவிய முன்னர் குறிப்பிட்ட பொருட்களை வாங்குவார்கள்.

இது மிகச் சீராக இருக்கும் மற்றும் அதிகளவில் சுற்றுச்சூழல்களுக்கு எதிராக தாக்கத்தக்கது, ஆனால் அது முழுவதும் அல்ல. ஒரு நிறுவனம் தனது பொருட்களை வெளிநாடுகளுக்கு அனுப்பும்போது, உதாரணமாக, அவை உயர்த்தெருவாக அல்லது குளிர்த்தெருவாக அமையும் சுற்றுச்சூழல்களில் சேதமாக கிடக்கலாம் மற்றும் பெயர்த்துரை காலாக செய்யப்படலாம். பொருட்கள் k-resin அடிப்படையில் கொண்டிருந்தால், அவை நிச்சயமாக காப்பகமாக இருக்கும். அவை சேதமாக சேதமாக காப்பு கொள்ளும் முறையில் சேதமாக காப்பு கொள்ளும்.

உற்பத்தி செய்யும் அனைத்து கல்வெடியாளர்களும் கம்பனிகளும் தங்களது உற்பத்திகளை சுற்றுச்சூழலுக்கு மிகவும் நண்பாய் செய்ய விரும்பினர். இரு பகுதிகளும் K-resin, ஒரு மறுபடியுற்ற பிளாஸ்டிக்கை மூலம் இருக்கை உருவாக்கப்பட்டன. K-resin உற்பத்திகள் தேவையில்லாமல் அல்லது உயிர் காலம் முடிவுற்றதால் மறுபடியுற்றவையாக மாற்றி புதிய உற்பத்தியாக மாற்றப்படலாம். இது குறைக்கும் அழுத்தத்தை வீதியிடும் செய்தியுடன் நோக்கமாக பணம் கிடைக்கும்... இது எங்கள் பூமிக்கு மிகவும் நலமாகும்.

அதிலும், K-resin உற்பத்தியை மற்ற பிளாஸ்டிக் வகைகளை உருவாக்குவதற்கு போல குறைந்த உற்பத்தியுடன் செய்ய முடியும். அது உற்பத்தியின் போது காற்றில் காற்று வெப்ப வாயுக்கள் குறைவாக வெளியே வெளியேறும். கல்வெடியாளர்கள் K-resinஐத் தேர்வு செய்தால் அவர்கள் தங்களது சுற்றுச்சூழல் அடிப்படையை குறைக்கலாம்.

காப்பிய உரிமைகள் © Richest Group அனைத்து உரிமைகளும் காப்பியமாக விட்டுக்கொள்ளப்படுகின்றன